It Pays to Upgrade Grain Dryers

July 21, 2016

Written By Adam Buckallew

Are you getting the most bang for your buck from your grain dryer? Research from the Propane Education and Research Council (PERC) suggests that unless you’re using the latest grain drying technology, you may be leaving money on the table.

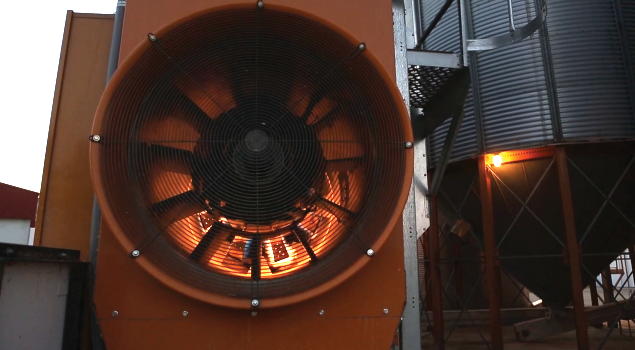

Grain dryers provide farmers with harvest flexibility that can save time and yield by reducing crop loss. Usage data collected by PERC shows modern propane-powered grain dryers can substantially reduce growers’ fuel consumption and maintenance costs when compared with older equipment.

“Our study found that by converting from an older, inefficient grain dryer to a more efficient dryer, the farmers we surveyed reported they reduced costs associated with yield losses and energy consumption by 43 percent,” says Cinch Munson, PERC director of agriculture business development.

Participants in PERC’s 2014 Propane Farm Incentive Program tested 21 different models of propane-powered grain dryers by seven manufacturers. On average, participants rated the new propane dryers 72 percent higher than the models they replaced. The farmers cited favorable operating costs, reliability, environmental friendliness, equipment availability and ease of maintenance as key factors in their ratings.

While many farmers have experience with propane grain dryers, they may not be familiar with the latest models and just how far the technology has progressed.

Today’s grain dryers require about half the thermal heat of older systems, which were already efficient. Newer grain dryers use approximately 1,650 BTUs to remove a pound of water, compared with older technology that takes as much as 3,500 BTUs.

In addition to more efficient energy consumption, the newest generation of propane-powered grain dryers distribute heat in a more precise fashion that ensures grain dries evenly, resulting in higher yield quality. The new technology also comes equipped with convenient features such as remote monitoring and automated filling, unloading and shut-off.

Beyond the savings associated with upgrading to new equipment, Munson notes propane grain dryers can help cut hidden costs you normally don’t factor in, such as yield loss.

“A timely harvest can maximize grain yield and profitability,” Munson says. “Leaving crops in the field is only leaving things to chance. On-farm drying with a propane grain dryer puts you back in the driver’s seat, with flexibility in harvesting and more control over marketing your grain. Instead of paying premiums to the elevator to dry your grain, you can dry it yourself. This gives you better control of your fuel costs and puts money back in your pocket.”