All News >> Digital Newsletters

Are You Following a Lubrication Program?

January 26, 2021

Written By Zach Studer

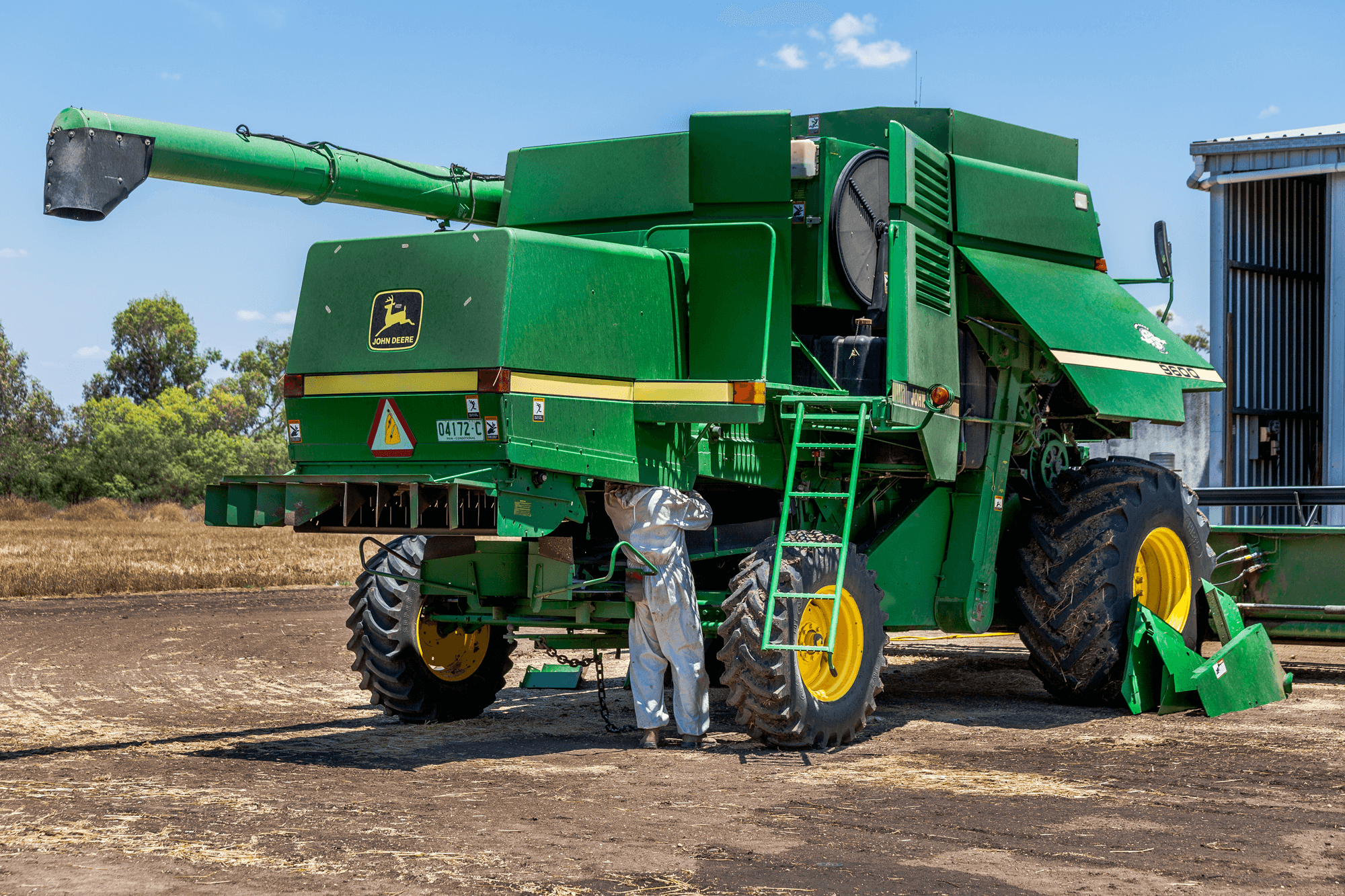

Whether you own a single tractor for farming, 20 pieces of construction equipment, or a fleet of 100 trucks, you likely depend on our equipment to get the job done. And how well your equipment performs is dependent on you.

Machinery needs lubrication to function safely, properly, and when you need it the most. The best way to ensure your equipment is ready to go to work is to adopt a routine lubrication program. By following the recommendations below, you can keep your equipment in top operational condition, avoid unplanned downtime and extend the life of your equipment.

Start with the proper lubricant

Just because you’ve always used a certain lubricant in the past, doesn’t mean it’s the best lubricant for the job. Today’s machinery is significantly more complex than the equipment from years past. These machines often require a more advanced lubricant to protect moving parts and operate as advertised. Check your owner’s manual to find out what lubricant the original equipment manufacturer (OEM) recommends. Keep in mind you are not required to use a particular brand of lubricant in your equipment to maintain your warranty. Any brand of lubricant that meets the required specifications set by the OEM will work. You can also contact the MFA Oil Laboratory for lubricant recommendations.

Use the right amount

Once you determine the correct lubricant to use, the next step is finding out how much of it your equipment requires. Adding too much or too little lubricant to your equipment can have devastating results. You want to add just the right amount. Again, refer to your owner’s manual or contact the MFA Oil Laboratory to verify your equipment’s needs. Knowing the proper amount of lubricant to use can help deliver big savings. It could mean the difference between the cost of buying the product in quarts or the potential savings of bulk purchasing.

Know when to change it

Knowing when to replenish or replace lubricants can be tricky, but it doesn’t have to be. Your owner’s manual will list a drain interval based on OEM recommendations, but this is a generic recommendation. The climate, the way your vehicle or equipment is used and the amount of stress it is placed under will determine the lubricant’s life span. If the equipment is operated at-or-above maximum recommended stresses, your lubricant’s life may be shortened. Having your oil analyzed regularly can tell you if the lubricant is still up to the challenge or if it’s time to change it out. Oil analysis is an easy and cost-effective way to identify upkeep issues and it allows you to track the health of your machinery, evaluate engine wear and spot the accumulation of contaminants before they become a serious problem.

Practice preventative maintenance

A proactive approach is the best way to maintain and extend the life of your equipment. Preventative maintenance is a key component of a lubrication program and will help you identify potential issues before they turn into big problems. Following a daily and monthly preventative maintenance checklist can you stay on top of your equipment’s needs. Your checklist should include daily inspection of lubricant levels and visual abnormalities and monthly collection of fluid samples for analysis. Check your owner’s manual or call the MFA Oil Laboratory for additional preventative maintenance suggestions.

Store and handle with care

Proper storage and handling of lubricants reduces the risk of contamination. You will want to make sure your bulk storage tanks are equipped with filters and the tanks should be periodically checked for the presence of water. Installing a desiccant breather on your bulk lubricant storage tanks can remove humidity from the air as it passes through your filter, which prevents moisture from entering the tank. If you have large drums of lubricants, store them indoors when possible, and if they must be kept outside, ensure they are covered to keep water out. We strongly encourage you to properly label your bulk storage tanks with a color-coded or symbol-coded system for all lubricants and lubrication points. This ensures the proper lubricant goes in the right equipment. Remember to use clean containers when transferring lubricants to the equipment to avoid contamination. The fewer points of contact the better. If there is ever any concern about the possibility of contamination, have the lubricant tested before it’s used.

Keep detailed records

One of the best management practices for lubrication programs is to maintain detailed maintenance records for each piece of equipment. A maintenance log will help you and other equipment operators know when preventative maintenance steps are needed and help you keep your equipment running in optimal condition. Additionally, well-documented maintenance logs are a valuable asset that can boost a buyer’s confidence should you decide to sell your equipment.

Effective lubrication is essential to keeping your equipment running smoothly and is key to avoiding unexpected shutdowns and costly repairs. By following a consistent lubrication program, you can ensure your equipment is ready and available to get the job done. Contact your local MFA Oil representative or the MFA Oil Laboratory if you need any assistance with your lubrication program.