The Value of Tertiary Propane Storage

April 24, 2016

Written By Adam Buckallew

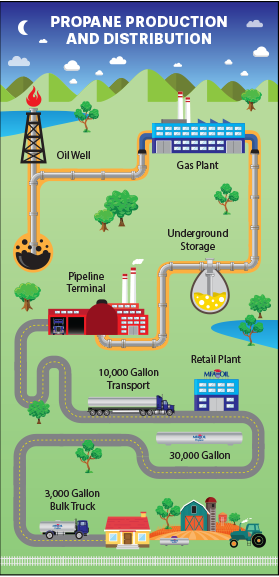

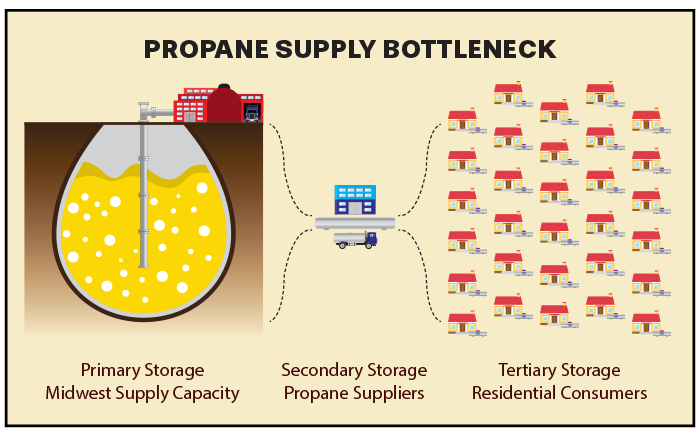

The propane capacity in customer tanks is an important part of the overall propane storage picture in the United States. In fact, customer storage, also known as tertiary storage, represents a larger portion of the national propane supply capacity than the industry’s primary storage, which is found mostly in underground caverns fed by pipelines. Taking advantage of tertiary storage is one way customers can help prevent future supply problems.

“In the past, most propane users have waited until it starts to get cold before they worry about refilling their tanks, but we’re trying to educate our customers about the advantages of filling tanks during the non-peak season,” says Kenny Steeves, MFA Oil vice president of bulk and propane plant operations. “Keeping tanks full year-round would go a long way toward eliminating the possibility of a shortage.”

Steeves says spreading out propane deliveries past the winter season benefits both customers and MFA Oil.

“Most customers should be able to lock in good pricing in the spring and summer when demand is reduced,” Steeves explains. “Supply is abundant during the warmer months, so it’s easy to source. Spreading out the demand also improves our delivery efficiency, which helps the cooperative and all of our customers.”

Lessons from the 2014 Shortage

The winter of 2014 was a stressful time for propane customers. Prices skyrocketed above $4 a gallon, and supplies were hard to find. The propane inventory crunch was caused by a combination of factors.

It started with a record corn crop that came in late and wetter than usual. This caused a spike in demand among Midwest farmers who needed propane to dry their corn harvest. Some crops came in as late as November, as winter began to set in early in some parts of the Upper Midwest and eastern United States. Corn drying and home heating were competing for the same supply.

Complicating matters, a major propane pipeline was shut down for maintenance in December. The Cochin Pipeline, which runs from Chicago to Edmonton, Alberta, was converted from propane service to light crude service. This was a major hit to propane users in the north central United States and drove them south to terminals in the MFA Oil service area to source product. Then, a polar vortex of artic cold hit in January, driving temperatures down over much of the country and draining what was left of most of the propane inventory. On top of it all, record propane exports cut into the U.S. propane supply leading into the peak heating season.

“The Midwest saw massive demand for propane in a relatively short period of time that year, which caused a strain on the supply chain that made it difficult for propane retailers to keep up,” says James Greer, MFA Oil vice president of supply and distribution. “We can only hold so much storage in our tanks and trucks. We had to travel more miles to obtain propane and extended our time to restock our inventories, and that’s what leads to shortage situations like we saw in 2014.”

Steeves recalls sending trucks to Mississippi, Texas and Kansas to retrieve propane for MFA Oil customers in the Midwest.

“We were looking for propane wherever we could find it,” Steeves acknowledges. “We were having to ration out the propane we were delivering because the supply situation was so dire.”

According to Greer, the main issue that prevented propane distributors like MFA Oil from catching up with the high demand of the 2014 winter season was a logistical bottleneck. The industry can only funnel so much propane from the pipeline terminals to distributors at a time. Once it gets to the distributors, the bottleneck is further limited by distributors’ storage capacity (tanks and trucks). Other factors such as inclement weather and limits on the number of hours delivery drivers can work further constrict propane supply in times of extreme demand.

Customers Play Their Part

In order to avoid a repeat of the shortages that occurred in the winter of 2014, MFA Oil asks propane customers to consider having their tanks refilled this spring and summer.

Propane is produced at a relatively steady rate year-round by refineries and gas processing plants, and there is no other source of incremental production when supplies run low. As it is in any economic scenario, when supply is limited and demand increases, prices will inevitably rise. This is why it is in all customers’ best interests to play their part and help spread demand throughout the year by refilling on propane in the spring and summer. Taking advantage of the storage capacity in their own tanks greatly increases the supply of propane.

The other benefit of propane purchases made during the spring and summer is those purchases give MFA Oil purchasing priority during times of shortages.

“All of our non-peak purchases count toward our allocation ratios, which is how our suppliers determine how much propane we can purchase when supply is short,” Greer says. “In other words, those purchases in the warmer months allow us the opportunity to maintain supply to our customers in the winter when supply can be an issue.”

Customers are encouraged to contact their local MFA Oil propane plant by August to discuss plans for their 2016 propane needs